Hydrographics for Aviation Interiors

Transform your aircraft interiors with decorative coatings that pass all flammability requirements.

Your Premier Source for Hydrographic Films and Aviation Coatings

TWN Industries is the premier source for Water Transfer Printing films, paints, and coatings for the aviation industry. Our state-of-the-art coatings transform the aesthetics and functionality of aircraft interiors, providing both visual appeal and durability.

Water Transfer Printing is an innovative decoration process that allows you to decorate lightweight honeycomb materials to look like real wood grain, marble, concrete, and more. Weight reduction is critical for increasing fuel efficiency and controlling costs. Our process allows you to apply limitless finishes without increasing weight.

Water Transfer Printing has become the go-to decorating process for aviation interiors, quickly replacing real wood veneer applications.

Trending Aviation Hydrographic Films

-

WTP-D112A Concrete

$90.00 – $450.00 Select options This product has multiple variants. The options may be chosen on the product page -

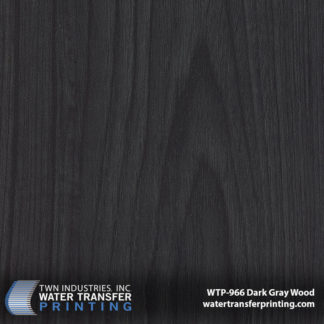

WTP-966 Dark Gray Wood

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

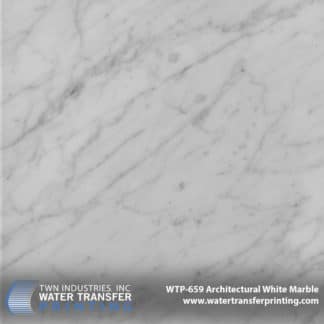

WTP-659 Architectural White Marble

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-279 Two-Tone Ash Grain

$28.75 – $105.35 Select options This product has multiple variants. The options may be chosen on the product page

Benefits of Water Transfer Printing for Aviation

Customization: Aircraft interiors often reflect the branding and style of the airline. Water Transfer Printing allows you to apply intricate designs, logos, and patterns to cabin fixtures, tray tables, cabinetry, and other components. This customization enhances the airline’s brand identity and creates a more visually appealing cabin environment.

Weight Savings: Weight is a critical factor in aviation, as it directly impacts fuel efficiency and operational costs. Water Transfer Printing adds a very thin layer of material, resulting in negligible weight increase compared to real wood veneer applications. This contributes to overall weight savings for the aircraft.

Aesthetics and Passenger Experience: The interior design of an aircraft plays a significant role in passenger comfort and satisfaction. Water Transfer Printing creates vibrant and detailed designs that enhance the overall aesthetics of the cabin. A visually appealing cabin environment contributes to a better passenger experience and differentiates airlines from competitors.

Durability and Resistance: Modern Water Transfer Printing techniques utilize durable coatings that provide protection against abrasion, UV exposure, and flammability. This ensures that the printed designs remain vibrant and intact even after prolonged use in the demanding aviation environment. Additionally, these coatings offer resistance to chemicals and cleaning agents used during routine maintenance.

Cost-Effectiveness: According to our customers, Water Transfer Printing can be 10-20% more affordable than new veneer installations.

Reduce Lead Times: Water Transfer Printing streamlines the decorating process and allows you to apply patterns to very complex geometries. Compared to a new veneer installation, Water Transfer Printing takes about 6-8 weeks to complete a project that would normally take about 8-12 weeks with real wood veneers.

Pair with our Aviation Coatings

Get A Decorated Sample!

Water Transfer Printing – Better Than Wood Veneers

- 10-20% cost savings

- Quicker turnaround times

- More durable, won’t peel or delaminate

- Less weight and increased full efficiency

Who We Help

Aircraft Manufacturers and Airlines

TWN collaborates with the most prestigious aircraft manufacturers in the world to give their planes unique style and purpose.

MRO Facilities

Maintenance, repair, and overhaul (MRO) facilities count on TWN to provide them with Water Transfer Printing films and coatings that meet their customer’s specifications.

Aviation Paint Facilities

Aviation paint facilities work with TWN to expand their capabilities and apply immersive patterns to aviation interior components.

Aircraft Owners

Private aircraft owners work with TWN and our network of TWN Certified Processors to customize their cabins with one-of-a-kind finishes.