Hydrographic Film

We have the largest inventory of camouflage, carbon fiber, wood grain, metal, and stone hydrographic films. Our inventory includes over 130 camouflage hydro dip films from brands like Kryptek, Next Camo, Moon Shine Camo, and more.

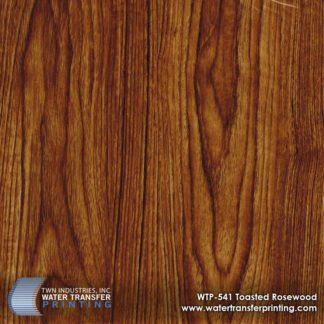

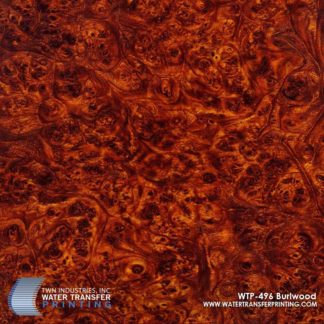

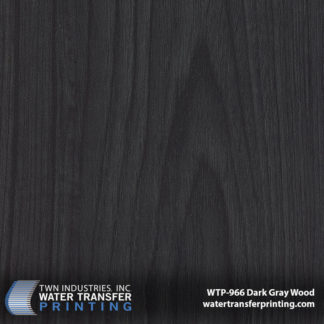

Be sure to check out our wood grain hydrographic films. We have a diverse selection of beautiful burl wood and straight grain patterns. These are used widely in high-end automotive and airline interiors.

Camouflage Hydro Dip Film

Top Selling Products

-

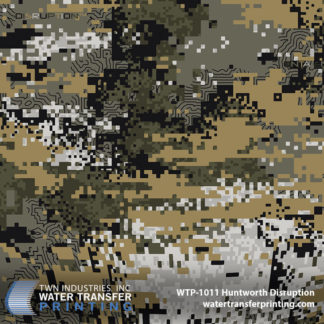

WTP-1011 Huntworth Disruption

$52.25 – $209.63 Select options This product has multiple variants. The options may be chosen on the product page -

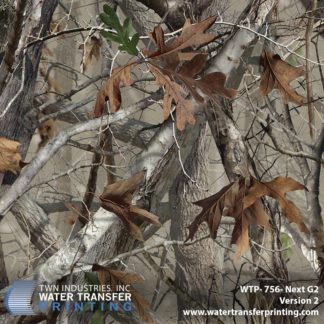

WTP-1055 King’s Camo XK7

$52.25 – $209.63 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-1107 Vector Camo

$52.25 – $209.63 Select options This product has multiple variants. The options may be chosen on the product page

Carbon Fiber Hydro Dip Film

Top Selling Products

-

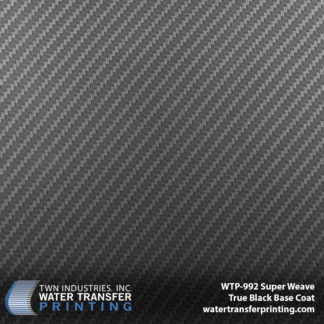

WTP-992 Super Weave

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-1017 Forged Carbon

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-940 Sport Carbon

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

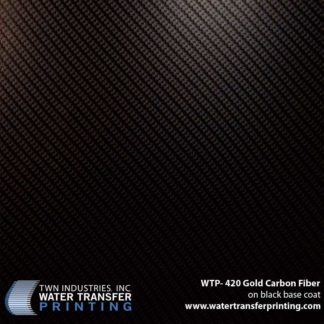

WTP-420 Gold Carbon Fiber

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page

Designer Hydro Dip Film

Top Selling Products

-

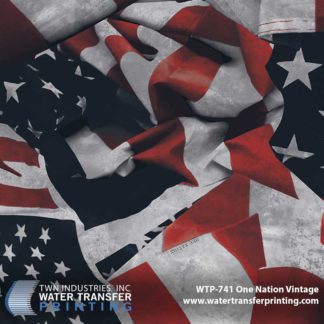

WTP-741 One Nation Vintage

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-D103A Palmas Azul

$90.00 – $450.00 Select options This product has multiple variants. The options may be chosen on the product page -

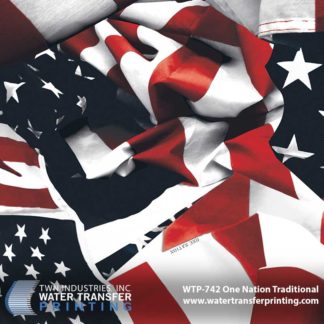

WTP-742 One Nation Traditional

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-958 Deception

$52.25 – $209.63 Select options This product has multiple variants. The options may be chosen on the product page

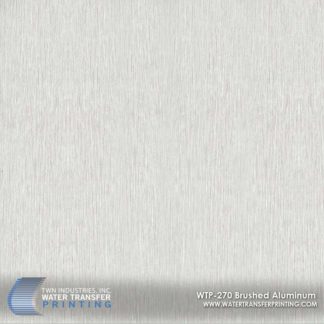

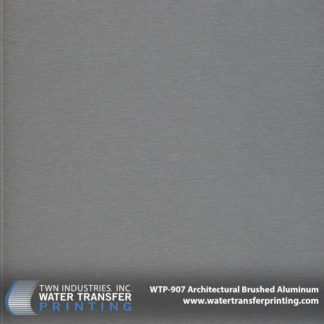

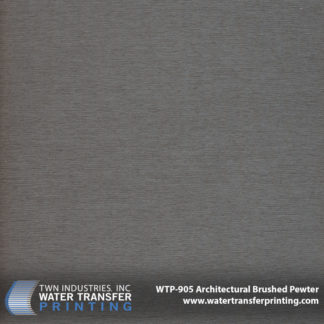

Metal Hydrographic Film

Top Selling Products

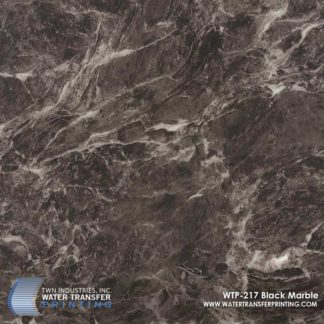

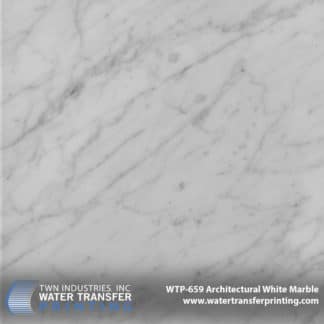

Stone Hydrographic Film

Top Selling Products

-

WTP-217 Black Marble

$28.75 – $105.35 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-D112A Concrete

$90.00 – $450.00 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-659 Architectural White Marble

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-D124A Calacatta Gold Marble

$90.00 – $450.00 Select options This product has multiple variants. The options may be chosen on the product page

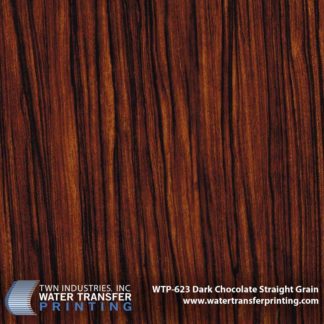

Wood Grain Hydrographic Film

Top Selling Products

-

WTP-623 Dark Chocolate Straight Grain

$28.75 – $105.35 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-541 Toasted Rosewood

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-496 Burlwood

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page -

WTP-966 Dark Gray Wood

$49.96 – $155.88 Select options This product has multiple variants. The options may be chosen on the product page